What size air compressor will I need for pneumatic tools?

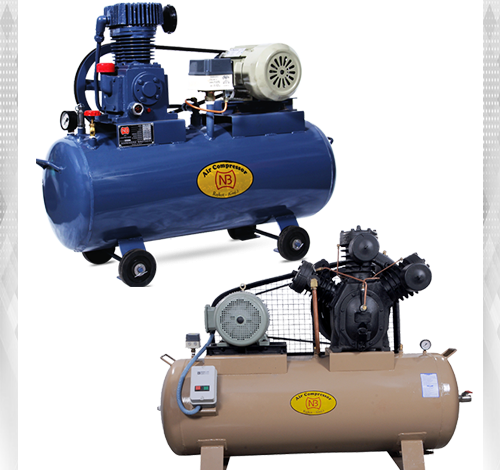

When it comes to choosing the best size air compressor for your home garage, you must have the right set of features. Size, in the context of an air compressor, is not its physical size. This indicates the compressor’s ability to handle the work you need to do.

The characteristics of your new air compressor should be the right mix of energy sources, electricity and gasoline. It must have adequate air capacity in terms of CFM and PSI. It should also have an appropriate compressor design and general setup to fit the specified space in your garage. These characteristics are essential, but so are the dimensions of the compressor. You need to consider these additional factors:

1. air reservoir

This refers to the size of the air compressor tank. Regardless of whether you have enough air capacity for PSI and CFM, your tank must be large enough to hold enough compressed air to keep your air tools running without interruption. The only way to avoid shutdown due to low air volume is to have a tank large enough to hold enough air while the compressor unit goes through the charging process.

US manufacturers measure air compressor tank volumes in US gallons. A wide variety of tank sizes are available on the market, ranging from small but efficient 1 gallon models to large 80 gallon commercial products. For your home garage, a compressor size between 2.6 gallons and 20 gallons should be fine. Sizing your compressor really depends on the type and number of air tools you intend to use.

2. AIR TOOL TYPES

The type of air tools you typically use is a main factor influencing the size of air compressor you need for your home garage. You should make a list or graph of the air tool types you’ll be using, how often you’ll use them and the number of tools in use at any time during your compressor’s duty cycle. A cycle refers to the time it takes an air compressor to sense its tank capacity is getting low until the time it’s able to recharge the reservoir.

Specific air tools demand a lot more CFM and PSI draw than others. For instance, a large air-driven framing nailer needs more air supply than a small impact wrench. A continuously operating air drill demands more CFM than a small, single-use air stapler.

The best formula for calculating the right sized home air compressor is to add up the CFM requirement for all the tools you intend to use as well as identify the peak PSI each one needs. This gives you the upper limit of what tank size in gallons, capacity in CFM and pressure in PSI you require. As a rule-of-thumb, it is a good idea to add 10 to 20 percent above your anticipated limit for an unexpected draw and future add-ons.

3. HORSEPOWER

When you research air compressors, you will always see a horsepower rating attached to each unit. The power source needs to be sufficient to run the compressor unit, but it is not something you should be too concerned about.

You can be certain that air compressor manufacturers like Makita, Campbell-Hausfeld and Hitachi will naturally size their horsepower to match the CFM, PSI and gallon capacity of their compressor assembly. Do not start selecting your air compressor by the horsepower rating. Pay attention to the air capacity and pressure as the manufacturer will supply the proper power rating.

Garage Air Compressor Setup

GARAGE AIR COMPRESSOR SETUP

Once you have selected the right size and capacity of home compressor. it is time to think about how you will set it up in your garage. There are many air tools, air hoses and reels, and fittings and accessories available to complete your shop air compressor system. As with all systems, your compressor tools and accessories have to match the basic compressor unit to achieve maximum performance. The correct placement of the air compressor is important. They should be placed in the center of the garage so that the air lines and pipes do not run for a long time. Prolonged operation will reduce compressor efficiency and reduce CFM power and PSI power.

Noise is another factor in finding and setting up a compressor. Some compressor models produce higher decibel levels than others. This information can be found in the product specifications and if this is an important issue it is always worth calling or emailing the supplier to discuss the noise.

Some owners place compressors in closed garages to control noise. This can be effective at handling decibels, but the heat generated by the compressor unit must be recovered. Placing the compressor in a soundproof enclosure may not be the best solution for long term performance.

It is wise to involve suppliers of compressors and air tools accessories when purchasing the right compressor for your home garage. Genuine tool suppliers know your products and help you get it right the first time. They can also help you choose the right air tools and air compressor accessories for your business.

Air Compressor Essential Tools and Equipment

The construction work you do in your workshop or home business is the result of using tools that support the new air compressor in your garage. Pneumatic tools have many advantages over power tools. Many people are so used to using air tools that it is difficult for them to return to electricity.

What is better rotary than inverter compressor?

Conclusion. Finally, it is advisable that you always choose AC with inverter technology. Even if you go for an inverter, it is better to have a double / triple rotary compressor instead of one. Now that you understand compressors well, your task of choosing the right AC is much easier.

What is a better scroll or rotary compressor?

The rotary compressor has more power and can therefore cool a lot of air than a scroll unit. Rotary compressors are a better alternative to a larger central air conditioning system, but they can be mounted on a small central unit or window air conditioner.

Read more: How Do Find The Trusted Gold Buyer In The Market?