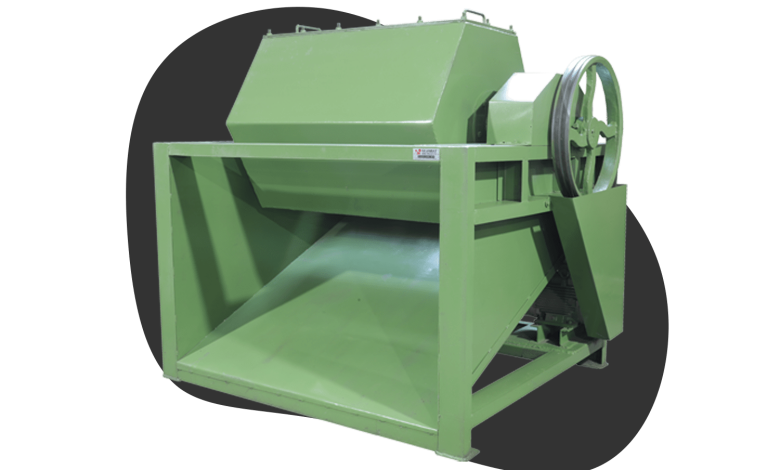

Vibrators Gold Polishing machine

Our prestigious clients can benefit from a wide range of polishing machine, including the Vibrator Gold Polishing Machine, which are highly sought after due to their unique features and are manufactured using the finest quality plastics, metals, and steel alloys. It is manufactured under strict quality standards in accordance with well-defined industry standards and offered to our valued customers at competitive prices in gray and red colors. Polishing barrel

Function: Compact design Strong construction

details: Material: plastic, metal, steel Type: Polishing machine Color: Green, Green

Glass polishing machines Power (HP): 1 hp to 10 hp Engine volume: 3 l to 1000 l Automatic class: Manual, Semi-automatic

We are in the business of supplying our clients with a wide range of barrel polishers which are commonly used for polishing wire nails. Our organization is known as the leading exporters for horizontal barrel polishing in India. These machines are specially designed to achieve efficient and fast nail polishing. Our range is made from premium quality raw materials and is recognized for its durability and corrosion resistance.

Details: Mirror polishing from 40 to 800 mesh. Max. polishing length: 5000 mm White color

Stone polishing machines

Engine volume: 50×50 Automatic class: Manual, Semi-automatic Power (HP): 5HP

It can avail stone polishing machines available in various models and sizes at market leading prices. All our machines are designed and developed using high quality raw materials and components from reliable vendors in the market. This machine is suitable for the production of various forms of decorative lines for ceramic, marble, granite and has achieved great performance and has high production efficiency, good product quality, and low processing cost, etc.

Details: Head: one head, two heads, three heads Grinding width: Between 400 mm to 2000 mm Dimensions: 60×60, 80×80, and 60×90 cm

What is finishing machine?

Finishing machines are machines used for the final treatment of metal, which is the last stage of the metal manufacturing process; the stage consists in the use of machines for the final treatment of the metal surface. This process gives the resulting metals a smooth and properly shaped appearance. Tumbling media, plating, and bulk abrasives are some of the materials that help complete the process.

Metal finishing

Metal finishing can also include performing a cleaning, polishing, and surface repair process. The process also includes electroplating. The metal finishing industry consists of a wide variety of methods or processes, each offering its own advantages to the user. It also includes the process of cleaning, transforming, or polishing the face. Metal finishing uses a variety of machines that vary in capabilities and efficiency. The efficiency of finishing machines varies depending on size and capacity.

This article takes a closer look at the basic finishing machines and their different and unique features.

Standard features

Standard features for finishing machine Due to the effective position of the motor, super vibration occurs Long machine life thanks to high tension nut bolts The best finish guarantee by an efficient liquid removal process The motor is energy efficient The trays fire before. And after the polyurethane coating for painting Make sure the internal welds ground smooth An anti-rotation motor locking plate available There is a stress loss process for bowls Advantages of surface treatment of metals Surface treatment has several advantages, which are:

Corrosion Provides final coating

Reduce the impact of corrosion Provides final coating adhesive It strengthens the surface as a product by increasing its resistance to deformation The products protect against wear. And tear that can occur with fiction Improving the appearance of the product Protects against facial defects

Chapter 2: Metal Finishing / Polishing Techniques

Several methods use to achieve a metallic finish. It details below. Metal polishing By polishing metals, surfaces can smoothed using an abrasive material. It removes defects on the surfaces of metal objects and gives them shine and an improved appearance.

In some cases, metal polishing used in

conjunction with polishing – which is not as harsh on the metal surface. As a method, metal polishing has cosmetic value. It also removes oxidation below the metal surface, preventing the metal from hardening to give it a long life. Metal polishing process The metal finishing process can achieve with a variety of abrasives, where the material polish determines the abrasive to use. There several steps to follow when polishing unfinished material. First, it necessary to remove imperfections from the material with a stronger abrasive. In the next stages, better abrasives use. Which improve the final treatment of the material.

A glass

like surface can achieve by adding a polishing compound to the polishing wheels. Polishing commonly used as lubricants such as kerosene or wax can used in some cases. Press grinders, stationary polishers or special equipment can used to achieve a brighter shine when polishing. For soft metals such as copper, very fine grain plated copper can use to make the surfaces smooth. Metals line with a mop for airflow. Tools like hammers, wrenches, screwdrivers, and chisels use different polishing methods because of their uniqueness. The tool is first subjected to roughening with a grinding wheel.

Finish materials

Dry polishing materials use immediately to finish materials. Lubricating grease can use at times when extra polishing need. Polishing can improve surface quality, reduce friction and wear. Abrasive used for polishing In the polishing process, different abrasives use for different strengths of metals. Metals with low tensile strength such as copper, brass. And aluminum use gray silicon carbide abrasives.

Cast iron carbide

This type of abrasive can also use on cement and gray cast iron carbide. High tensile metals such as carbon and alloy steel, non-ferrous and ferrous alloys, and abrasives such as white and gray alumina use. Chromium oxide green abrasive use in ferrous metals such as steel. Leather and cloth can use for polishing. Materials can also include felt, plastic, wool, rubber, and more. Pug or buffing wheels use wool or cotton cloth.

Polishing application Polishing

Polishing application Polishing require in manufacturing processes for products such as cookware, cookware, automotive parts. And metal architecture before they released to the market. Metals can sometimes polished to restore or repair parts. Workplace safety can also improved by buffing and polishing. For example, polishing helps prevent corrosion of a special pipe. In pharmaceutical and dairy pipelines, mold and bacteria can destroy and corrosion prevented, increasing product safety.