Pouring

The clay shape is warmed to around 550 – 1100°c. The warming system further qualities the form. Disposes of any extra wax or foreign substances. And vanishes water from the shape material. Liquid metal has filled the form while it is as yet hot. Fluid metal streams into the pouring cup. Through the focal gating framework. And into each shape depression on the tree. The pre-warm shape permits the metal to stream effectively through dainty, segments. It likewise makes an investment with work on dimensional exactness. As the shape and investment casting will cool and therapist together.

Process of Cooling

After the shape has been poured. The metal cools and hardens. The time it takes for a shape to cool into a strong state relies upon the material that projects. And the thickness of the casting is made.

Shakeout

When the projecting hardens, the ceramic molds separate. And the casting can be taken out. The fired shape is ordinarily separate physically or by water jets. When eliminated, the singular castings isolate from their gating framework tree utilizing manual effect, sawing, cutting, consuming. Or by cool breaking with fluid nitrogen.

Finishing

Completing tasks like granulating or sandblasting normally utilize to smooth the part at the entryways. And eliminate flaws. Contingent upon the metal that the projecting pour from. Heat-treating might utilize to solidify the last part.

Sandblasting metal

Sandblasting is generally utilized to clear and streamline metal parts to eliminate blemishes.

When to use investment casting

Because of its intricacy and work necessities. Investment casting is a somewhat costly interaction – but the advantages regularly offset the expense. For all intents and purposes, any metal can speculation project.

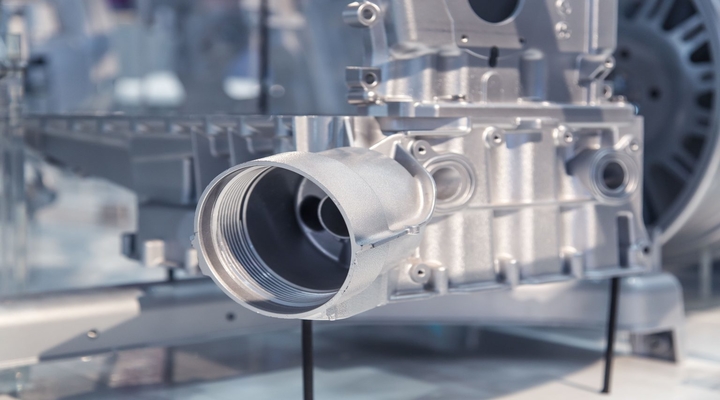

Complex parts

Investment casting equipe for creating complex parts with incredible as-casted surface completions. Invested castings don’t have to have to tighten worked in to eliminate the parts from their molds on the grounds that the fired shells split away from the part after cooling. This creation includes permits castings with 90-degree points to plan with no shrinkage recompense worked in. And with no extra machining needed to get those points.

The investment casting interaction makes leaves behind prevalent dimensional precision. Net-shape parts are effectively reachable. And completed structures regularly created without optional machining. Every extraordinary projecting run requires another bite of the dust to create wax designs. Tooling for speculation projecting can be very costly; contingent upon the intricacy.

Volume arranges

For high volume arranges the time. And work saved by wiping out or diminishing auxiliary machining effectively compensates. For the expense of new tooling. Little projecting runs are less inclined to compensate. For the speculation. By and large, speculation projecting is an intelligent decision. For a run of sections of counting is 25 or more.

It ordinarily requires 7 days to go from a new wax example to a total projecting; most of that time takes up by making. And drying the fired shell form. A few foundries have speedy dry abilities to deliver castings all the more rapidly. The time and work concentrated nature of speculation projecting don’t just impact the cost. Foundries have restricted hardware and creation limits. So longer lead times for speculation projecting are normal.

Investment casting for wheels

Investment casting utilizes to make leaves behind prevalent dimensional precision. Where completed structures frequently create without auxiliary machining.

Custom casting services

Foundry works cooperatively with customers to plan the example and trim technique for every custom casting. Solicitation a Quote to get more data on how our casting help can coordinate with your task prerequisites.

Read more: What Are PVC-U Pipes?