Choosing the right amount of air filtration is about more than just finding a filter that fits. It’s also about ensuring you’re using the best filter for your home. For instance, forcing a 4″ filter into a spot meant for 1″ filters can strain HVAC equipment, making it less efficient. This can increase energy bills and lead to premature wear and tear.

Installation

When a filter is dirty, it stops air from flowing through the ducts and causes the system to work harder to heat and cool the home. It can also damage the blower and coils over time as they become gunked up with debris. Choosing the right filter size is critical to the efficiency of your HVAC air filter housing system and indoor air quality. Check the existing filter to see its width, height, and depth. Then, look for a similar size at your local hardware store. Air filters are generally standardized, so finding one should be easy. When you install the new filter, ensure it has an arrow printed on its frame indicating the correct direction for airflow. That way, the air flows into the furnace rather than back out through the return ducts and back into the home. Also, consider a location for the filter that is easily accessible to homeowners and service technicians. Ideally, it would be located in a return grille with a hinged cover that is easy to open without needing a tool.

Material

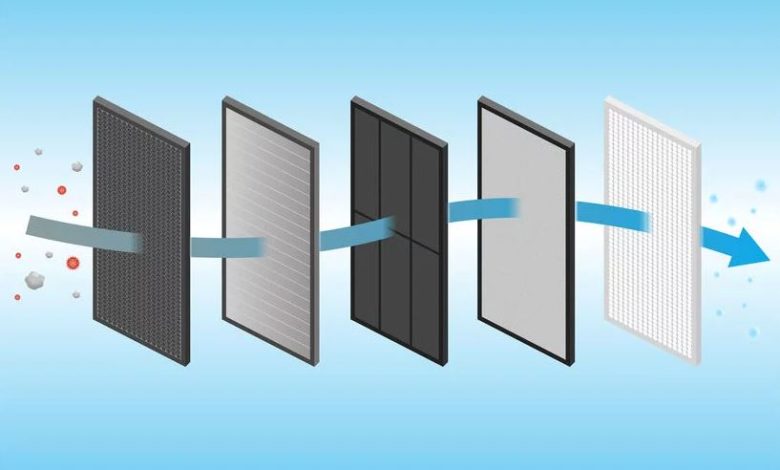

Removing airborne pollutants from a home’s airflow is essential in improving indoor quality. The air filters in HVAC systems snag dust and other particles before they reach the fan or coils and are either disposable or washable. Filters range from a few inches to a couple of feet and come in various designs. Basic models are made with strands of fiberglass or metal mesh and can stop big debris. Higher-end filters have material more like a surgical mask arranged into pleats to trap smaller particulates. They can be found as disposables or reusables and are often called electrostatic or HEPA filters. Many modern filters are made with thermally bonded, continuous, hydrophobic polyolefin fibers that resist shedding and won’t absorb moisture. They also contain a gradient density structure to maintain high efficiency over the filter’s lifetime. They are typically used to protect people in residences, office buildings, and hospitals. They can also protect products during manufacturing, such as computer chips and pharmaceutical drugs.

MERV Rating

The MERV rating is essential for selecting the right filter for your home. The rating indicates how efficient the filter is at removing pollutants from the air in your home. It also indicates how the filter performs regarding different particle sizes. Higher MERV ratings tend to offer better filtration. However, they can strain the HVAC system if it isn’t built to handle it. This can lead to damage and increase energy bills. Check your furnace manual or information stickers for the maximum MERV rating your system can accommodate. Then, select a filter that offers the best balance between your family’s air quality needs and what your HVAC system can handle. Generally, filters with a MERV rating between 8 and 13 are ideal for most homes. This will provide you with excellent filtration without overworking the system.

Design

Filters with a lot of surface area help keep lint and dust from clogging the furnace coils and blowers. High-efficiency filters have a pleated design that further increases their surface area, snagging even the smallest particles like mites and mold spores. These filters are typically more expensive than disposable fiberglass filters but offer a greater return on investment in terms of improved indoor air quality. Filter thickness matters because it affects how much pressure the filter creates across its surface. A thicker filter will have more resistance than a thinner one, and that extra resistance can impact the amount of air (CFM) the HVAC system can move through the system. The type of filter also impacts how often the system needs to be cleaned. Dirty filters can clog the fan and coils, leading to decreased performance. A Magnehelic gauge helps facility engineers monitor the filters, alerting them when the system is dirty before the filters cause severe damage.