Types of air compressor and controls

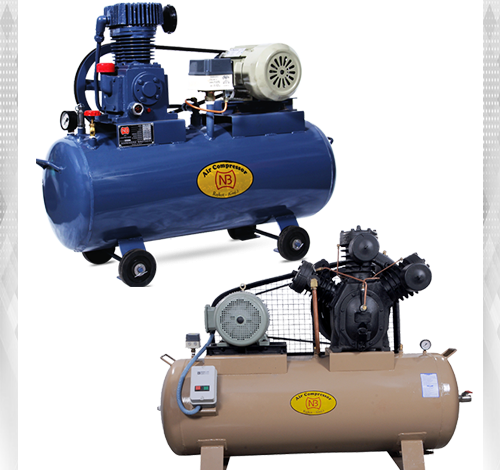

There are two main types of air compressors:

Positive deletion a Dynamic air compressor. Positive transition. In a positive kind of distraction. The predetermined amount of air is trapped in the pressure chamber and the amount retain is certainly reduced. Cause the associated voltage increase before release. Tighten the bolt, grass. And sensitive blowers are the three most common types of positive blowers found in small and medium businesses. air compressor

Dynamic

Dynamic air compressors incorporate outward and hub machines, and utilize in extremely enormous assembling offices. These units are past the extent of this report.

a. Rotational Screw Compressors

Rotational screw blowers have acquired ubiquity. and a portion of the overall industry (contrasted with responding blowers since the 1980s. These units are most commonly used in sizes from 5 to 900 HP. The best-known type of rotary blower is the spiral double, screw blower. The two paired rotors connect, sucking in air and reducing the amount of air in the rotors. Rely on the virtues of air virtue. Rotary screwdrivers are available as grease or dry. Cross section of a representative rotary screw compressor.

Otherwise in the text

The biggest advantage of screw blowers is small units that respond to the air ball. This is so that they can run at full charge continuously, whereas reactive blowers must use a 60% duty cycle or less. The rotary screws are even quieter. and can produce cooler air that dries more easily. Be aware that rotating screw blowers may not be the most productive decision compared to starting/stopping the blowers. Rotating screw with ointment injection

The screw rotary blower with ointment is the most important type of modern blower for a set of tools. For grease-filled rotary screw blowers. Oils can be a hydrocarbon organization as a substance produced. A common combination of compressed air. And the leached ointment leaves the air tip and passes through a sump where the fat is removed from the thick air. Changes in direction and speed

Changes in direction and speed are used to isolate many parts of the fluid. The remaining steam sprayers are then in the packaged air. In that moment. It is separated by a separating component in the swamp, which carries a fraction of every million (ppm) of ointment left in the packaged air. In the case of two-phase blowers, the intermediate stage can cool down. And lowering the internal voltage with a lower voltage in each stage increases the pressure efficiency. Therefore, a small amount of energy is expected to trap air in the air compressor shaft tension.

Dry type rotary screw

In the dry type, the closed rotors cannot touch each other. And their general checks remain much closer to the opposition. With externally lubricated timing gears. Most plans use two intercooler and aftercooler printing phases. The greaseless rotary screwdriver has a range of 25 to 1,200 HP or 90 to 5,200 cfm.

b. Respond to Compressors

The air compressor has a cylinder that passes through the drive rod and an electric motor. Responsive blowers for universal useful industrial use are realistic in sizes from less than 1 HP to 30 HP. Reaction blowers are often used in air supply for structural control and robotics.

What is the function of an air compressor?

An air compressor is a machine that uses an electric motor or gas motor to drive equipment that draws a progressive amount of air into the environment. Any volume of air in the confined space to create its fuselage by making the volume milder. and then transfer the high pressure air to the receiving tank. According to the DTE Energy instruction page. High pressure air from the collector tank for hardware control. Air compressors.

Three basic types

There are three basic types of air blower The first, called a reactive blower, involves crushing air into a cylinder in a room. The second, called a rotary screwdriver, uses an alternating rotating screw to constantly reduce the volume to envelop the air. Third, peel off the divergent blower. The rotating fan is used to drive the force of the wind along the lines that surround it.

Air system

The blower is only one piece of general air construction, depending on the location. The receiving tank is an important element that prevents excessive wear of the blower by continuous cycling. The tank then throws a beating current into the air.

Cleaners and coolers

The air frame further includes cleaners that remove water vapor and blower vapors from the compact air as it exits. Coolers may also be available to reduce the compressed air temperature. Finally, there are hoses or lines that lead the high pressure air to where it will take care of something. The air available for work is estimated in cubic feet per minute (cfm). The higher the cfm, the greater your strength.

Air reserve

Compressed air is a form of energy removal, with primary air being available later. He can take care of things when he returns to air congestion when he supplies. Bottled air use. Among other things, to control comfortable and adjustable equipment of many kinds, to drive pneumatic motors that can replace internal combustion and electric motors, and to operate the heaviest equipment generating electricity.

Blower market

Responsive blowers with motors from one to 50 drives sold for households. small shops, and light modern purposes. Where the demand for air already persists. Rotary blowers with motors with more than 100 strokes. It is sold for heavy modern use, where there is an unforgivable interest in full air. Air compressor

Large sensitive air compressors do exist in the industry. However, they are currently economically unattainable, except for the purposes of certain cycles, such as high voltage applications.

Air pressure during application

So how do you know what air pressure needs for a given application? Air tools made for general use with portable air compressors typically require 0 to 5 cubic feet per minute (cfm) at 70 to 90 pounds per square inch (psi), while for larger equipment connected to stationary systems the requirements typically exceed 10 cfm at 100 to 120 psi.