Many industrial and commercial applications require valves. Fluid or gas flow is regulated by them, and they are found in everything from cars to sprinklers. The valve controls the flow of liquid, allowing it to start and stop. To prevent leaks and unintentional discharges, they need to be properly maintained. The ball valve or gate valve is the most common type of valve. There is no difference between the two valves in terms of their purpose. They differ, however, in terms of their structural characteristics. The difference between gate valves and ball valves can be summarized as follows.

Industrial gate valves are the most common valves in water supply systems. Flow can be allowed or stopped with this linear motion valve. Flow regulation cannot be achieved with these. Partial openings can cause damage, so they should only be opened or closed fully. In the case of gate valves, the closure slides to the fluid to create a shut-off, thus serving as a gate.

The gate valve is one of the most commonly used valves due to its simplicity and versatility. The ports on gate valves are designed to be full-ports by design. In other words, the valve port size equals the inner diameter of the connecting pipe. Fluid can flow freely through full-bore gate valves without obstruction and without creating a pressure drop inside the pipeline. The line can also be cleaned with a cleaning rod.

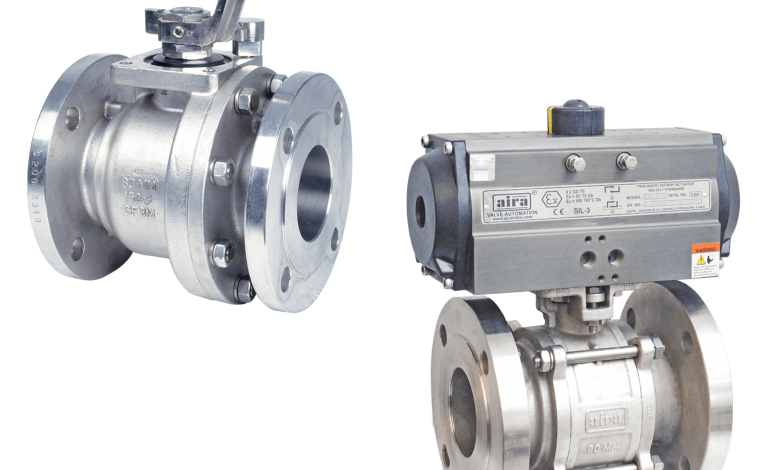

What Is a Ball Valve?

The ball valve regulates the flow of liquids or gases between two ends by using a rotatable bore and a ball. The ball can be rotated one-quarter turn (90 degrees) near its axis to allow the medium to flow through it or firmly stop it. Through these valves, the flow can be controlled by partially blocking, blocking, or opening the entrance. Gas valves are best suited to ball valves since they have a more robust seal. As well as enduring pressures up to 700 bar, they can also withstand temperatures up to 350 degrees Celsius. Their sizes range from 0.5 to 30 cm. Because of their simple structure, they are simple to repair and use.

Ball valves for industrial applications are reliable and durable. It is possible to close them securely even when they are idle. Even in dirty media, they seal well and are more resistant to contamination than other types of valves. Globe and gate valves are commonly used for control and shut-off applications. In throttling applications, they lack fine control.

Aira Euro Automation is the leading ball valve supplier in Nigeria. We offer various types of industrial valves like ball valves, control valves, pressure-reducing valves, butterfly valves, and many more.

Gate Valve Vs Ball Valve

There are two types of valves, both of which control fluid flow through pipes, but they do so in different ways. A gate valve opens and closes fluid flow by moving a gate. Fluid flows through the pipe by raising or lowering the gate valve. A gate valve is typically used for pipes with larger diameters and higher pressures than a ball valve. To control fluid flow, ball valves use a ball with a hole through the center. To align the hole with the flow of fluid, the ball is rotated. Gate valves can handle higher pressures, but ball valves are typically used for smaller diameter pipes.

Valve Flow Direction

Gate valves are the best choice for unidirectional flow systems. Gate valves are also well suited for applications that require a large volume of fluid to pass through quickly. Ball valves, on the other hand, are better suited to bidirectional flow applications. Additionally, ball valves are easier to operate than gate valves, making them a good choice for applications where the valve will be frequently opened and closed.

Valve Seal Capacity

When a gate valve is closed, the valve disk is completely sealed. Therefore, they are ideal for high-pressure applications requiring a leak-free seal. Ball valves, however, have a small hole in the center of the valve disk. In high-pressure situations, they are not as effective at sealing as gate valves due to their speedy opening and closing.

Valve Design and Construction Differences

Liquids and gasses are typically handled by gate valves, while liquids are handled by ball valves. In gate valves, the gate opens and closes to allow or block the fluid flow, while in ball valves, the ball does the same thing. There are strengths and weaknesses to both types of valves, but they can be used for a variety of applications.

While gate valves are usually cheaper and easier to repair, they are not as durable as ball valves. While ball valves are more expensive and difficult to repair, they are much more durable and can handle higher pressures.

Also, read “What is a valves ???”

Valve Material

Gate valves are solid pieces of material. There is usually a hole cut through the center of the metal. A ball valve, on the other hand, is a hollow ball with a hole drilled through the center. To open and close the valve, the user uses two handles connected to the ball.

Applications

Ball valves are designed to provide a tight seal, while gate valves open quickly. Typically, gate valves are used in applications requiring fast opening and closing, while ball valves are used in applications requiring tight seals.

Durability

Due to their fewer moving parts and less prone to corrosion, gate valves are generally more durable than ball valves. While ball valves are more likely to leak over time, they can be easier to repair if they do.

In the end, the type of valve you use depends on your specific needs and preferences. A gate valve is a good option if a valve needs to withstand a lot of wear and tear.

Globe Valve Vs Gate Valve Vs Ball Valve

Ball valves, gate valves, and globe valves are the three main types of valves. A valve’s advantages and disadvantages depending on the application, and the type of valve needed will depend on it. In this article, we’ll compare three types of valves: ball valves, gate valves, and globe valves.

Often used in applications where precise control is required, globe valves are well suited to regulating flow. The cost of globe valves can be higher than other types of valves, and they are harder to repair than other types of valves.

Gate valves are ideal for applications requiring completely open or closed valves. A gate valve is often used in water pipelines and other applications where a complete shut-off is required. Gate valves can, however, be more challenging to operate than other valves.